Equipment

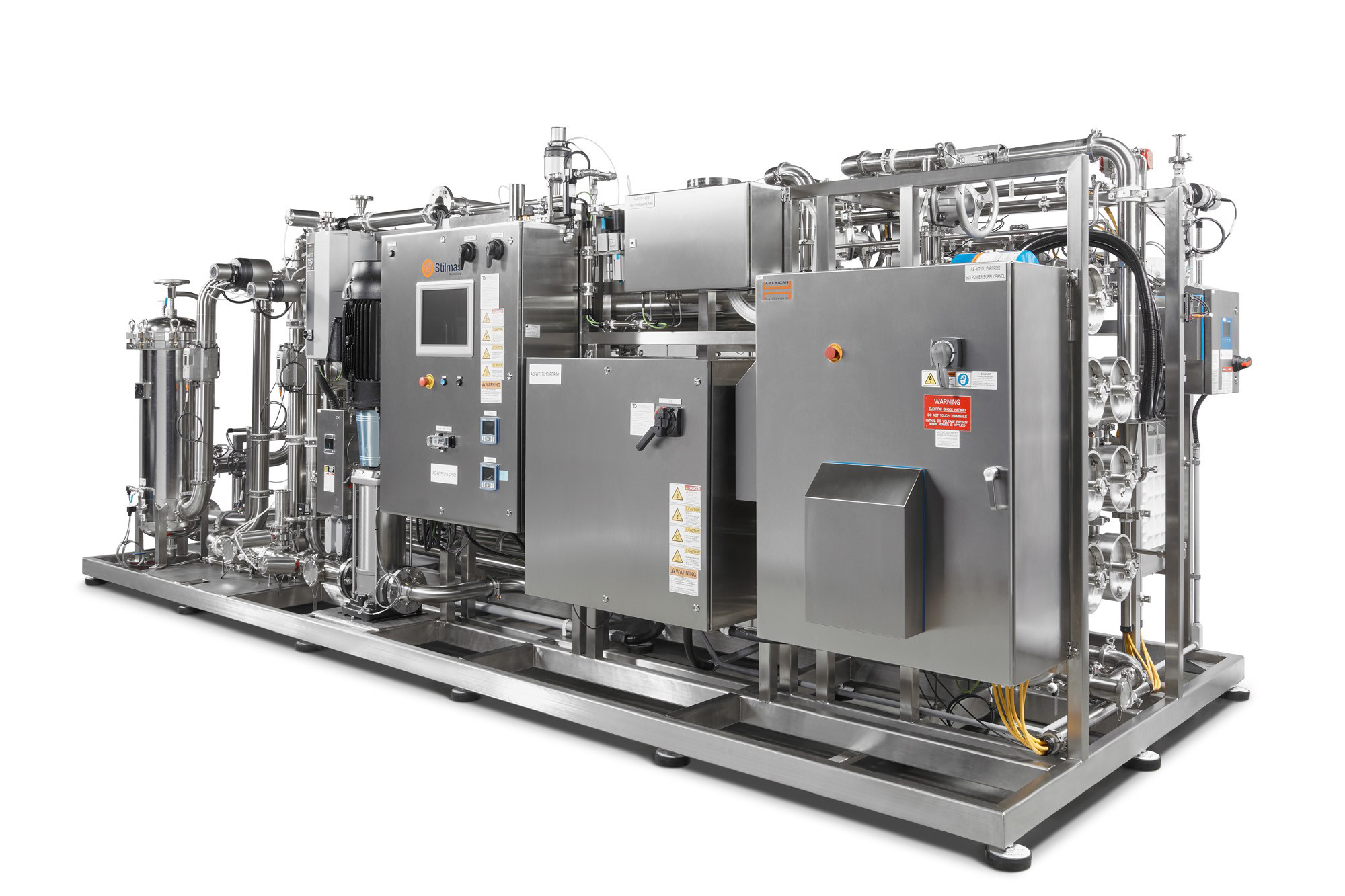

UltraPure LSX ME

Introducing the UltraPure LSX ME

Engineered to the highest water quality and reliability standards for the Microelectronics market. Compact and efficient, the UltraPure LSX ME integrates all components needed to produce Ultra-Pure Water, surpassing ASTM D5127 and SEMI F63-0521 requirements on a single skid.

Engineered for peak performance, energy conservation, and water optimization. Automated hot water sanitization ensures unparalleled bacterial control, maintaining a steady baseline water quality while minimizing downtime and decreasing reliance on chemical CIP processes. The UltraPure LSX ME stands ready to elevate your water purification system to new levels of efficiency and reliability.

Available in platforms ranging from 25 to 600 GPM of electronics grade water. Self-modulating valves allow the user to dial in required flowrates within acceptable turndown ratio. Additional Generation volumes available upon request.

Application fields

Application fields

|

|

|

|

|

|

Technical description

Base: Break tank, prefiltration, reverse osmosis, polishing EDI, germicidal UV, and final filtration

Enhanced: Chemical feed, HWS carbon, TOC reducing UV, Degasification, Low Boron EDI, and ultrafiltration provide a tailored water treatment solution.

Smart Control and Monitoring

- Allen Bradley CompactLogix PLC, with Ethernet connectivity for remote monitoring, troubleshooting, and tuning via Industrial VPN router.

- PanelView Plus 15” HMI standard.

- Software utilizing Rockwell PlantPAx process libraries.

- FactoryTalk View SE Panel PC available.

- Emmerson, Siemens, platforms available.

- Full Color Graphics Display, based on the systems Process Flow Diagrams.

- Controlled Multi-user access levels, Operator, Maintenance, Engineering, Administrator.

- External RJ45 ports for Ethernet connectivity.

- HMI Access to all system manuals with Panel PC.

Low Total Cost of Operation – High Sustainability

- Tailored system product flows meet exact user specifications, ensuring optimal performance and satisfaction.

- Advanced self-monitoring adaptive controls optimize performance, maximum efficiency, and quality under changing conditions.

- Advanced recovery modes optimize water usage based on quality and temperature, reducing waste and resource consumption.

- Dynamic quality modes preserve water quality during standby, ensuring reliability and consistent product quality.

- PID-controlled break tank matches demand, optimizing efficiency and performance.

- Proactive differential pressure monitoring across all filters ensures optimal performance and maintenance efficiency.

- Comprehensive monitoring ensures precise control and optimization of all system parameters for maximum efficiency and sustainability.

- User-defined sanitization schedules provide flexibility and convenience, ensuring convenient maintenance and enhancing system reliability and efficiency.